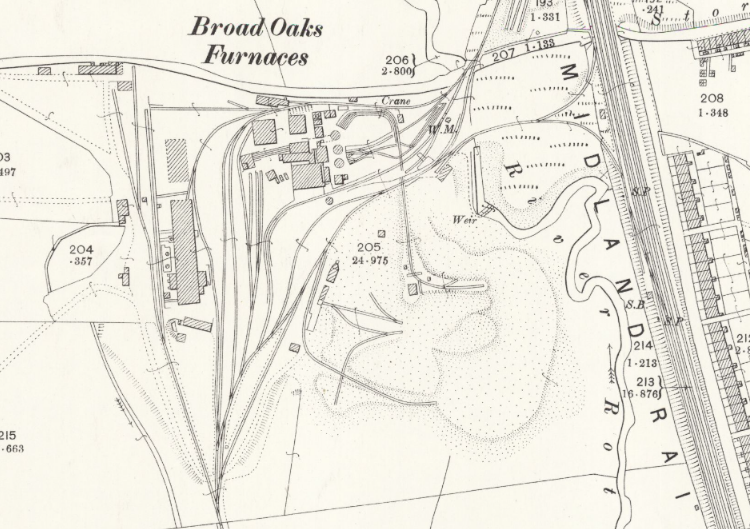

In this blog we’ll take a look at the so-called Wingerworth ironworks, later known as the Broad Oaks ironworks. Both names are a bit confusing. The name Broad Oaks was for many years associated with Markham works in Spital, but the ironworks weren’t there. Nor were they at Wingerworth. The works were actually at Storforth Lane, in Hasland Parish.

In 1848 James Yates (1798–1881), a Rotherham ironfounder, took a lease for 20 years from Michaelmas 1846 of the ironstone under much of the Hunloke estate in Wingerworth and adjoining parishes, a smaller acreage of coal beneath the estate west of the Midland Railway, and two pieces of land at Tupton and Birdholme, on each of which he proposed to erect blast furnaces.

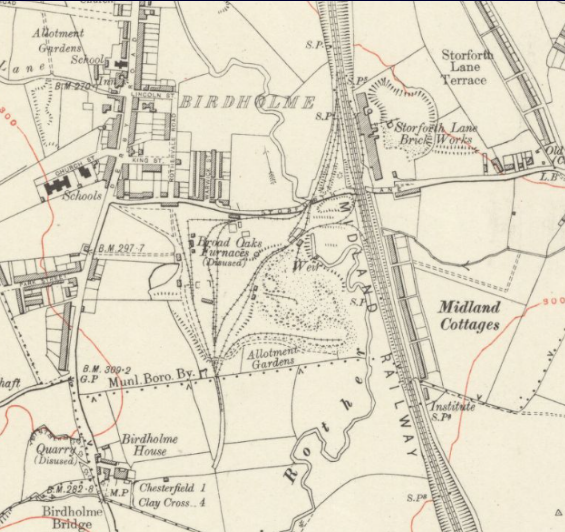

The rights of the Wingerworth Coal Co. and Clay Cross Co. under earlier leases were protected and Yates was to use the coal he mined on the estate only for smelting ironstone. Yates did not proceed with the scheme for furnaces at Tupton, possibly because the Clay Cross Co. built an ironworks not far away at about the same date. But by 1847 Yates had erected three furnaces on the west side of the Midland line immediately south of Storforth Lane.

Coal and ironstone were brought from pits on the Hunloke estate in Wingerworth on a standard gauge tramway which passed beneath Birdholme Bridge and in front of Birdholme House before running through the works to a junction with the main line. The business was known as the Wingerworth Iron Co. from the mid-1850s.

Yates was joined in partnership at the Wingerworth business by Thomas Carrington (1813–73), originally from Stockport, the brother of Betsey Carrington (1806–78), Yates’s second wife, whom he married in 1843. In 1851 Thomas, then aged 38, was living at the house on St Mary’s Gate, in Chesterfield, near the top of Tapton Lane which previously been the home of the Malkin family, with his wife Elizabeth, aged 29, who had been born in Australia, and their three sons, Thomas (9),Charles (7) and Arthur (5), all born in Stockport, and a daughter Harriet, aged one, born in Chesterfield. The chronology implies that the family moved from Cheshire between 1846 and 1850.

In 1861, by which time the family had moved to Holywell House on Holywell Street, Carrington was employing about 600 men in his ironworks and collieries, and gave a figure of 400 ten years later. In 1869 he and Yates renewed their lease of ironstone beneath the Hunloke estate west of the railway and the land on which the ironworks was built for a further 21 years.

Carrington, a Congregationalist, was elected a member of the Iron & Steel Institute in 1870 and the following year was elected the first chairman of Chesterfield school board, an office he retained until he died in 1873. His effects were initially sworn at under £70,000 and later resworn at under £60,000. He was described in the probate grant as an ‘Ironmaster and Hat Manufacturer’. One of his executors was his brother Samuel Ratcliffe Carrington, a hatmaker of Stockport, suggesting that Thomas had kept an interest in a family business. James Yates (who remained resident at Rotherham) was also an executor.

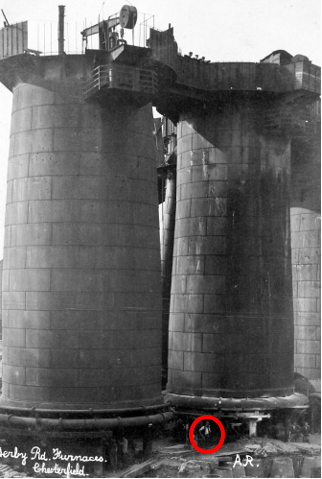

Thomas’s son Arthur Carrington (c.1846–1924) became a member of the Iron & Steel Institute in 1872 and seems to have been the only acting partner in the Wingerworth Co. after Thomas’s death. He was employing 80 men at the furnaces in 1881. From about 1884 Thomas Blair, who had previously worked as a furnace manager at John Brown’s Atlas Works in Sheffield, was the manager at the Wingerworth business.

In 1886 Blair gave a paper on silica and other deposits he had found in an old furnace bear at Wingerworth to the Iron & Steel Institute, of which he was elected a member in 1875. Blair supplied analyses of Northamptonshire ore to C.H. Plevins in 1887, when Plevins was considering erecting steel works on his estate at Woodford (Northants.), and may have been seen as a potential manager of the new enterprise.

After the ironstone at Wingerworth became exhausted in the 1870s (and the tramway from the works partly lifted), the company drew supplies from a mine near Burghley (Rutland). In the previous decade the company had joined other companies in a consortium known as the Midland Counties Iron Ore Co. which made unsuccessful attempts to develop the Jurassic iron ore of Northamptonshire.

The three furnaces at Wingerworth were rebuilt in 1872 and thereafter each had a capacity of 16,000 tons a year. At least two, and in some years all three, were in blast until 1886, when the works shut down for two years. The furnaces were back in use between 1889 and 1893 but then closed again. In February 1887 cash was collected at Derby Road Iron Church and used to provide tickets which were given to married men with families laid off from the works who could use them to buy goods from local tradesmen.

In 1897 C.P. Markham took a lease of the works, initially through his Chesterfield engineering business, Markham & Co., although they appear afterwards to have been transferred to the Staveley Coal & Iron Co. Markham, who later purchased the freehold of the site, put the furnaces back into blast, giving work to about 150 men, and also built a new pipe foundry, which employed a similar number. The furnaces were then said to have a capacity of 350 tons a week each. After Markham took over the site it was known as Broad Oaks Furnaces, presumably because it operated in connection with Markham & Co.’s Broad Oaks Ironworks, Chesterfield.

Broad Oaks Furnaces closed in 1907. The site remained derelict for some years before it was acquired in 1931 by Tarmac, and was later used by a company manufacturing prefabricated concrete buildings. The manufacturing of iron for the Staveley Coal and Iron Company was transferred to the new Devonshire Works at Staveley, which were constructed to replace Broad Oaks iron works and significantly improve production and by-product capture, refining and sale.

We’ll be tracing the further use of the ironworks site in a future post.