Bolsover Colliery

In this post we present a short history of Bolsover Colliery – finally closed in 1993. It is another in the series using information from our former England’s Past For Everyone website.

Introduction

The modern history of coalmining in the district began with the sinking of Langwith colliery, just inside Scarcliffe parish, to the Top Hard seam in 1872–9, which led to the building of a new village at Whaley Thorns, close to the eastern boundary of Bolsover parish.

Bolsover beginnings

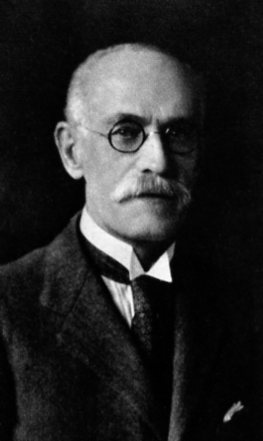

For Bolsover itself a more important date was 1888, when Emerson Muschamp Bainbridge (1845–1911), previously a manager of collieries in the Sheffield area, acquired leases of the coal beneath the Portland estate at Creswell (in Elmton) and Bolsover. He proceeded to promote the Bolsover Colliery Co. Ltd, with J.P. Houfton as general manager. The company’s capital was fully subscribed by the beginning of 1890 and sinking began at Bolsover in June that year. The Top Hard coal was struck in September 1891 at a depth of 365 yards. A second colliery at Creswell was sunk in 1894–6 and in 1905 work began on a pit at Crown Farm in Mansfield Woodhouse (Notts.).

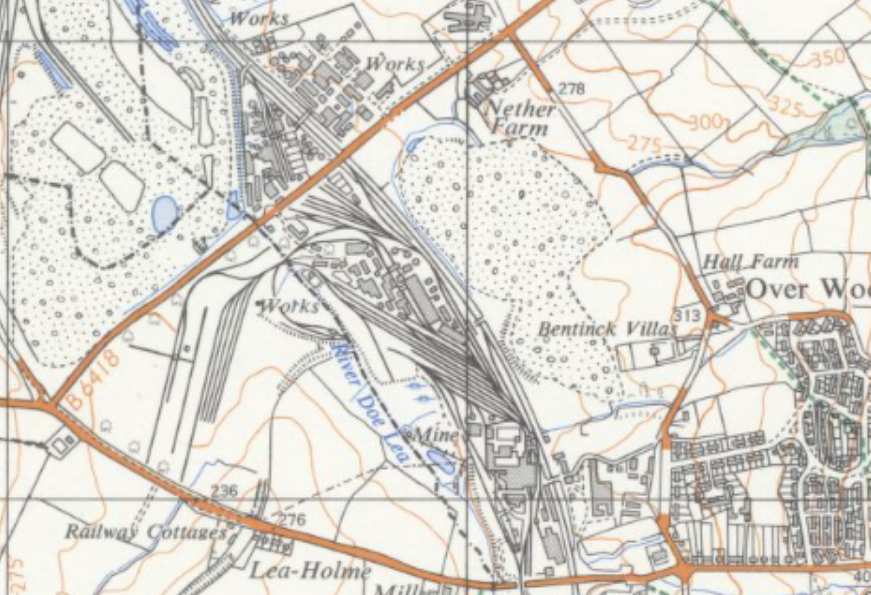

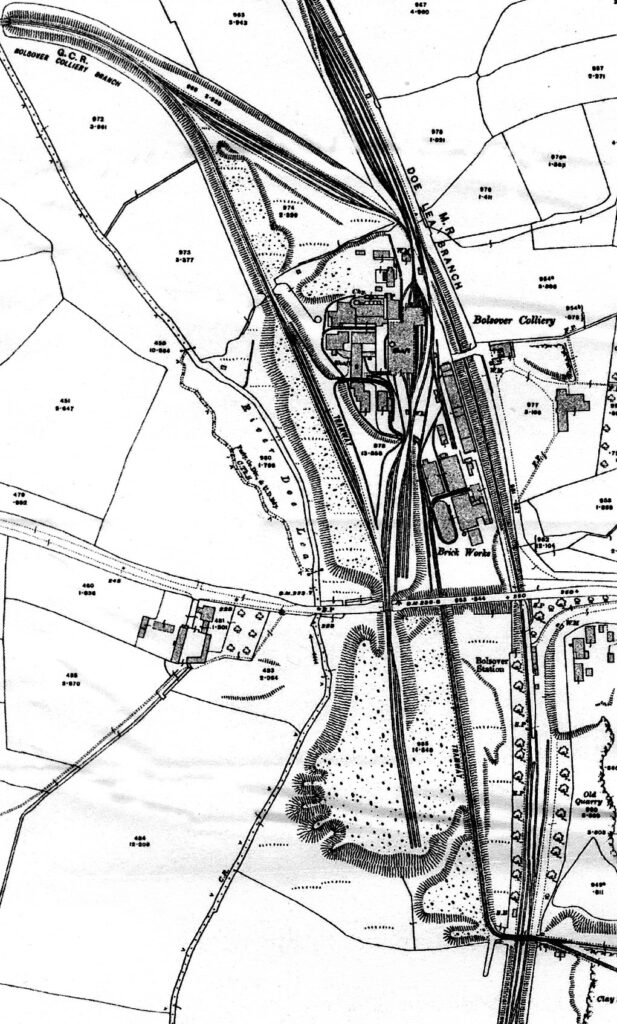

Bolsover colliery stood to the north of Chesterfield Road immediately east of the river Doe Lea, although spoil tips and an associated brickworks lay to the south of the main road. Further south again the company developed a model village, complete with schools, an institute and a co-operative store, built between 1891 and 1895, which became known as New Bolsover, and later executed a larger scheme of the same sort at Creswell.

By 1895 output at Bolsover colliery had reached 1,800 tons a day and the pit was employing about 850 men. In 1905 Bolsover was raising 2,850 tons of coal a day and the following year exported 300,000 tons from the pit.

The interwar period and beyond

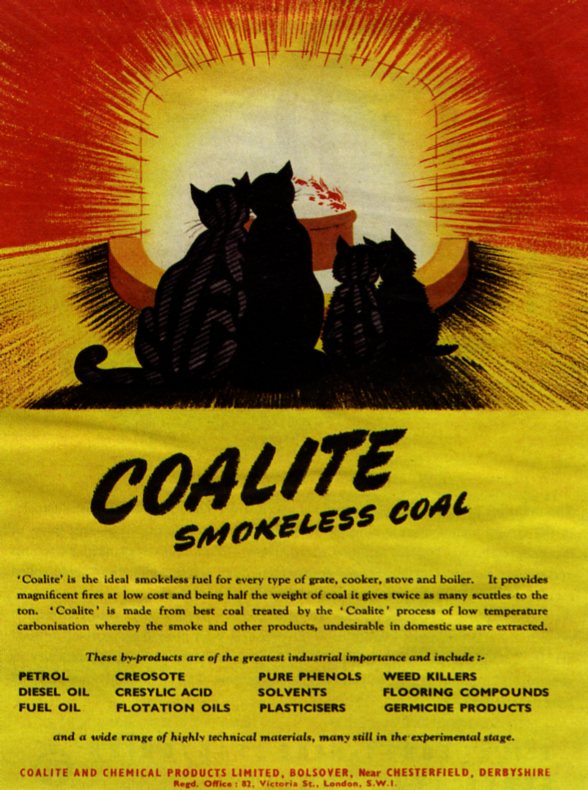

By 1923 the Bolsover Company was producing 11,000 tons of coal a day. At Bolsover itself the extension of workings to the Waterloo and Deep Hard seams in the late 1920s, as well as the opening of the Coalite works next to the colliery in 1936, were seen as developments that would lengthen the life of the pit and provide for the `prosperity and contentment’ of the community for many years to come.

Unlike other concerns in the Derbyshire coalfield, the Bolsover Company remained generally profitable during the inter-war period and was able to modernise its older collieries as well as developing new ones in north Nottinghamshire. At Bolsover hand getting and haulage by ponies had given way to mechanised cutting and the use of electrically powered rope haulages by the early 1930s. On the surface pithead baths were opened in 1935. An aerial ropeway to carry spoil from the pithead to tips south of Chesterfield Road was installed in 1943.

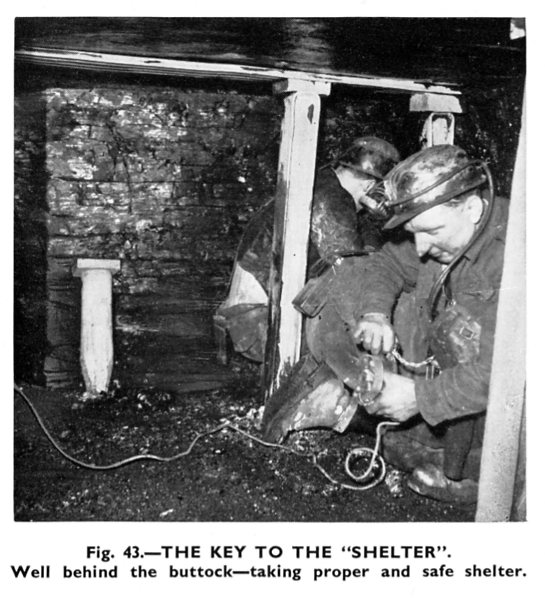

In 1944 the company demonstrated a Meco-Moore power cutter-loader at Clipstone; after vesting, the Gloster Getter, developed by W.V. Sheppard, formerly of the Bolsover Company, almost doubled output per man-shift and made possible the development of continuous longwall mining at Bolsover. The technique pioneered at the colliery became known as the `Bolsover System’ and considerably reduced the cost of producing coal.

Bolsover colliery remained an important part of the coal industry in north Derbyshire for half a century after nationalisation, although by the mid 1950s, when the pit was producing 10,000 tons a week and employed 1,000 men, the more profitable and easily accessible seams had long been worked out. The headgear and winding engine at the original (No 1) shaft were removed in 1974; the winding engine at No. 2 shaft had been replaced by an electric winder in 1968; and in 1976 skip-winding was introduced at No. 3 shaft.

In the late 1970s the colliery still employed between 900 and 1,000 men, who in 1978 were said to be breaking all previous output records and picking up large bonuses. In this period half of the output of the colliery went to power stations, 30 per cent to carbonisation plants, and the rest to other industrial and domestic markets.

Decline and closure

A decline set in after the dispute of 1984–5: in 1987, when output was 650,000 tonnes, the number of employees had dropped to 750. Three years later only 600 men, including 150 contractors, were working at Bolsover. In August 1992 British Coal announced that more than 450 miners would lose their jobs the following spring when Bolsover was due to close. Ironically, early in 1993, the year in which coal was last turned at Bolsover, the remaining 350 men at Bolsover were said to be producing coal very cheaply and once again breaking output records.

After Bolsover colliery closed some of the surface buildings were adapted to create an industrial estate for small businesses.

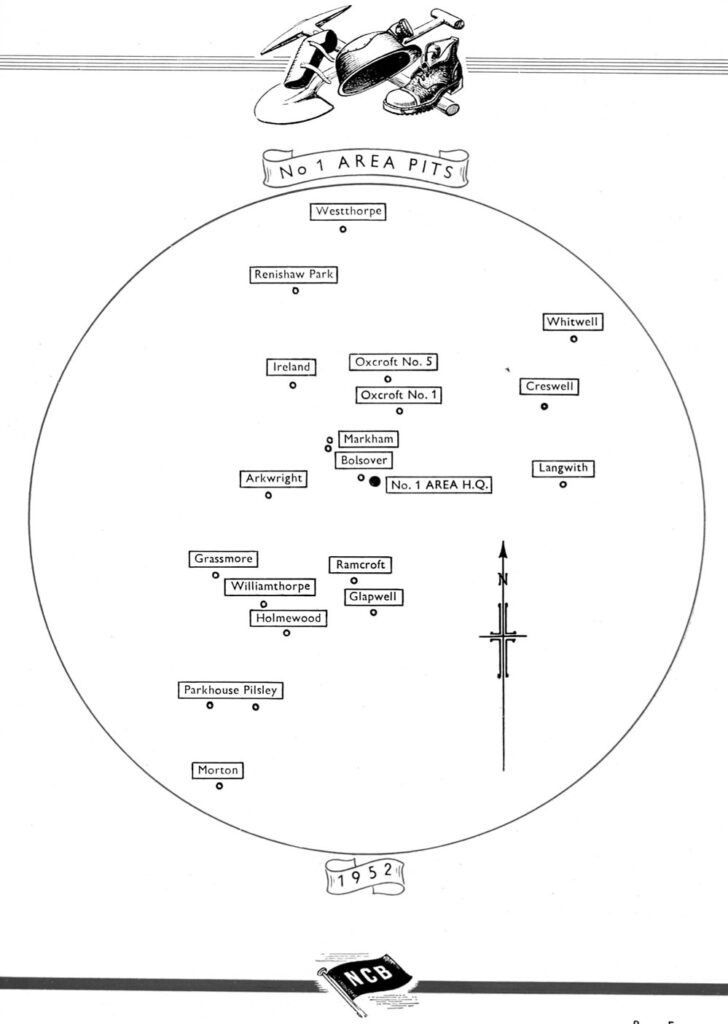

In 1947 the former headquarters of the Bolsover Colliery Company, built on higher ground to the east of the pit became the NCB area office. The premises remained in use for this purpose until the contraction of British Coal in the late 1980s, when the former North Derbyshire Area was absorbed into a Midland Area with headquarters at Leicester. After the offices closed this site was also converted into units for small businesses.

Sources used in this account are fully referenced in our Derbyshire VCH Volume III Bolsover and Adjacent Parishes. Additionally we have used a National Coal Board safety publication produced in 1952. We would especially like to credit Bernard Haigh and his centenary history of the Bolsover Colliery, published by British Coal in 1989.